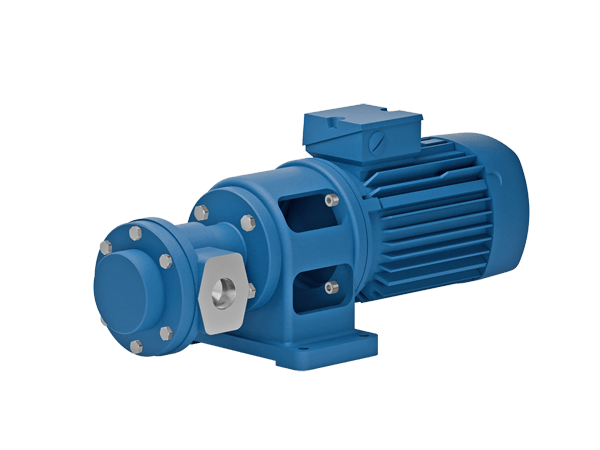

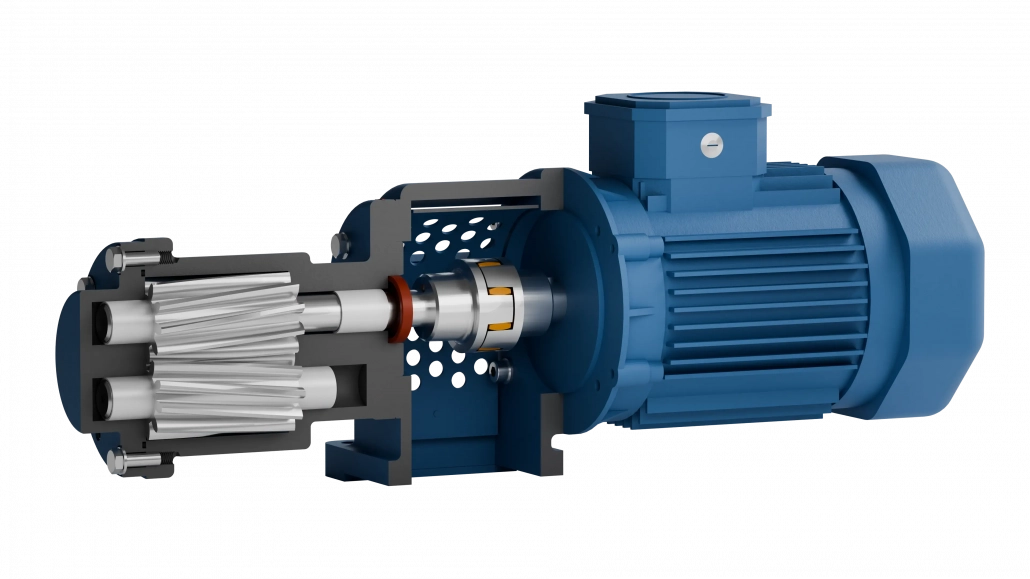

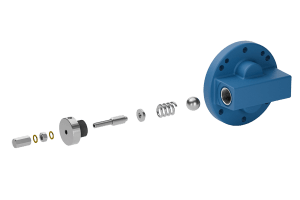

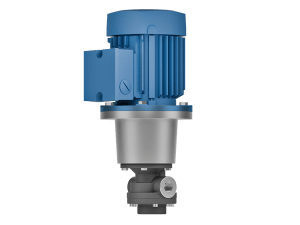

FKM series - Electric gear pumps

The gear pumps of the FKM series are designed for flow rates up to 124 l/min and pressures up to 80 bar.

They consist of a gear flange pump that is connected to an electric motor via a compact console.

FKM3 series

Medium: Hydraulic oil 35 mm²/s @ 50 °C

| Type | cm³/rev | Qmax (l/min) | pmax (bar) |

|---|---|---|---|

| FKM 310 | 5,10 | 7,40 | 50 |

| FKM 314 | 7,10 | 10,20 | 50 |

| FKM 318 | 9,10 | 13,20 | 40 |

| FKM 323 | 11,70 | 16,70 | 33 |

| FKM 328 | 14,10 | 20,30 | 25 |

| FKM 333 | 16,70 | 24,10 | 20 |

Q values based on n = 1450 min-¹. Maximum pressure depends on the available motor power.

FKM4 series

Medium: Hydraulic oil 35 mm²/s @ 50 °C

| Type | cm³/rev | Qmax (l/min) | pmax (bar) |

|---|---|---|---|

| FKM 422 | 21,20 | 30,5 | 15 |

| FKM 426 | 25,00 | 36,2 | 13 |

| FKM 430 | 28,90 | 41,6 | 12 |

| FKM 434 | 32,80 | 47,3 | 10 |

| FKM 438 | 36,70 | 53,0 | 9 |

Q values based on n = 1450 min-¹. Maximum pressure depends on the available motor power.

FKM5 series

Medium: Hydraulic oil 35 mm²/s @ 50 °C

| Type | cm³/rev | Qmax (l/min) | pmax (bar) |

|---|---|---|---|

| FKM 545 | 43,40 | 62,7 | 8 |

| FKM 556 | 54,00 | 78,1 | 7 |

| FKM 570 | 67,50 | 97,7 | 5 |

| FKM 590 | 86,80 | 124,0 | 4 |

Q values based on n = 1450 min-¹. Maximum pressure depends on the available motor power.