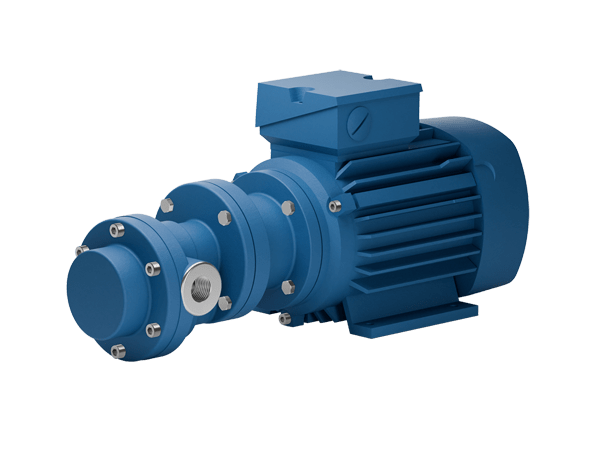

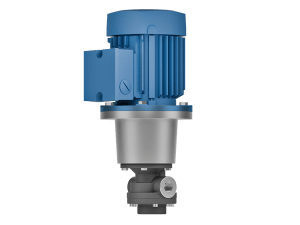

FLM series - Electric gear pumps

The gear pumps of the FLM series are our most compact units and are designed for flow rates of up to 24 l/min at pressures of up to 75 bar.

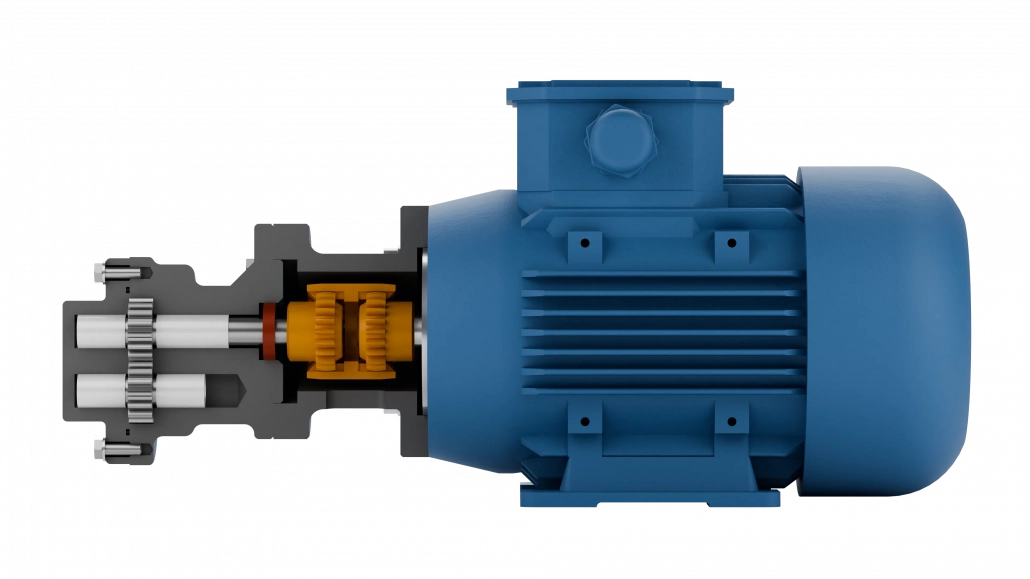

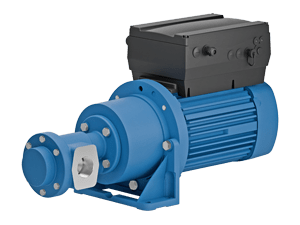

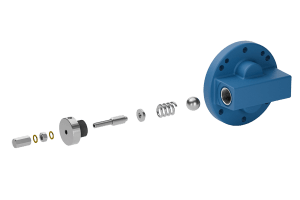

They consist of a gear flange pump that is directly combined with an electric motor.

Depending on the application, the motors are available in three-phase, alternating current or direct current versions.

FLM1 series

Medium: Hydraulic oil 35 mm²/s @ 50 °C

| Type | cm³/rev | Qmax (l/min) | pmax (bar) |

|---|---|---|---|

| FLM 1-06 | 0,43 | 0,60 | 20 |

| FLM 15 | 0,85 | 1,15 | 40 |

| FLM 17 | 1,20 | 1,60 | 40 |

| FLM 110 | 1,80 | 2,30 | 40 |

Q values based on n = 1450 min-¹. Maximum pressure depends on the available motor power.

FLM2 series

Medium: Hydraulic oil 35 mm²/s @ 50 °C

| Type | cm³/rev | Qmax (l/min) | pmax (bar) |

|---|---|---|---|

| FLM 210 | 2,30 | 3,00 | 70 |

| FLM 214 | 3,20 | 4,50 | 60 |

| FLM 219 | 4,30 | 6,00 | 40 |

Q values based on n = 1450 min-¹. Maximum pressure depends on the available motor power.

FLM3 series

Medium: Hydraulic oil 35 mm²/s @ 50 °C

| Type | cm³/rev | Qmax (l/min) | pmax (bar) |

|---|---|---|---|

| FLM 310 | 5,10 | 7,40 | 75 |

| FLM 314 | 7,10 | 10,20 | 50 |

| FLM 318 | 9,10 | 13,20 | 40 |

| FLM 323 | 11,70 | 16,70 | 33 |

| FLM 328 | 14,10 | 20,30 | 25 |

| FLM 333 | 16,70 | 24,10 | 20 |

Q values based on n = 1450 min-¹. Maximum pressure depends on the available motor power.

Downloads

Data sheet (incl. characteristic curves)